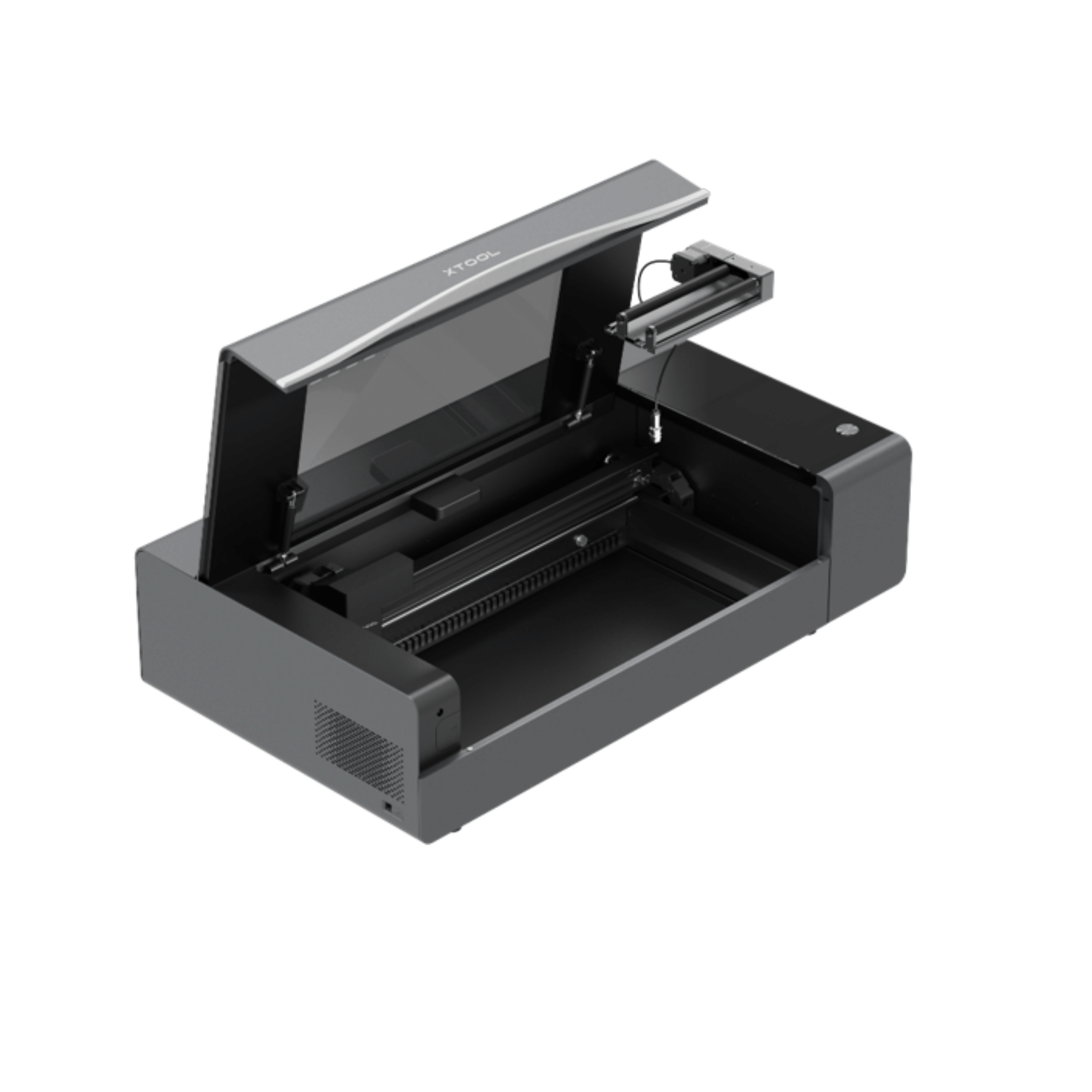

xTool P2 Class I and Class IV versions

Topic

Who should use it

Lid open detection

Safety

Base plate detection

2D laser cutting and engraving

Cylinder engraving

Free 2D laser cutting and engraving

Slide-through door

Feeding accessories

Curved surface engraving

Class I

School and University

Yes

Auto detect Lid

Not allowed to remove base plate for operation. The machine detects if the base plate is installed. Operation can only be started if the base plate is installed, and it will be interrupted if the plate is removed.

Yes (with the base plate)

Up to 42mm diameter

No

No

No

Under assessment

Class IV

Small Business

No

No

Some configurations have base plate detection before operation.

Yes

Up to 180mm diameter

Yes

Yes

Yes

Yes

Extensibility

Cylindrical engraving

Slide-through door

Lifting base

FAQ's

1.Why class 1 is better for school?

The class 1 is made for safety in mind. It can not function if base plat or lid is open

2.What is xtool P2 EDU bundle?

The Xtool P2 EDU bundle include the purifier as well as few sample material to get you started.

3.What precautions should be taken during Class 4 laser?

Keep it away from people's eyes and heads. Watch out for reflected beams from glass and shiny surfaces.

4.Is P2 compatible with xTool smoke purifiers and RA2?

Yes.

5.With Class 1 xTool P2 and the rotary attachment, what is the maximum size of cylinders I can process?

With the slats removed and using the rollers of RA2, you can process cylinders of diameter up to 42 mm.

6.If I need to purchase protective goggles, what specifications are required?

The lid is designed to filter laser light, so you don't need to buy separate protective goggles. However, if you do, make sure they have an OD4 protection level and are wavelength-rated for 10640nm.

7.What are the positioning precisions of distant-view and close-view positioning?

Theoretically, when the material is placed directly under the camera, the error for the close-view positioning is 0.3 mm to 0.5 mm; and for distant-view positioning, the error is also 0.3 mm to 0.5 mm.

8.How to clean the slats after the process of cutting?

Use a tissue with stain removers or kitchen cleaners to wipe the slats.